Lyocell Fabric: Sustainable Textile, Uses & Manufacturing

Lyocell fabric has emerged as one of the most innovative and sustainable textile materials in the modern fashion and manufacturing industries. Known for its softness, strength, and eco-friendly production, lyocell bridges the gap between natural and synthetic fibers. As consumer demand for sustainable clothing increases, lyocell has become a preferred choice for brands, designers, and environmentally conscious buyers.

What Is Lyocell Fabric?

Lyocell is a semi-synthetic fiber made from regenerated cellulose, primarily sourced from wood pulp such as eucalyptus, beech, birch, or spruce trees. While it originates from natural raw materials, lyocell undergoes advanced chemical processing, placing it in the category of regenerated fibers rather than purely natural textiles.

The defining feature of lyocell fabric is its closed-loop manufacturing process, which minimizes environmental impact by recycling solvents and reducing waste. The result is a fabric that is breathable, smooth, biodegradable, and exceptionally versatile.

Other Names and Brand Names of Lyocell

Lyocell is often recognized under different names depending on branding and market usage. The most widely known trademark is TENCEL™ Lyocell, produced by Lenzing AG. In technical and industry contexts, lyocell may also be referred to as regenerated cellulose fiber or advanced viscose alternative. Although lyocell is related to rayon and modal, it is chemically and environmentally superior due to its production method.

History and Development

The development of Lyocell fabric dates back to the late twentieth century when textile scientists sought an alternative to traditional rayon, which relied heavily on toxic chemicals. Early research began in the 1970s, but commercial production gained momentum in the 1990s with the introduction of environmentally safer solvent systems.

Lenzing AG played a major role in refining the process and bringing lyocell to global markets under the TENCEL™ brand. Since then, lyocell has steadily gained popularity as sustainability became a central concern in textile innovation.

Raw Materials Used

Lyocell fabric is derived from renewable wood sources, most commonly eucalyptus trees due to their fast growth and low water requirements. Unlike cotton, eucalyptus does not require intensive irrigation or pesticides, making it a more sustainable raw material. The cellulose extracted from wood pulp forms the foundation of lyocell fibers.

Manufacturing Process

The Lyocell fabric manufacturing process is considered one of the most environmentally responsible fiber production methods in the textile industry. It begins with harvesting wood from responsibly managed forests. The wood is chipped and converted into pulp, from which cellulose is extracted.

The cellulose is subsequently broken down using a safe, low-toxicity organic solvent, most commonly N-methylmorpholine N-oxide, which enables the fibers to be formed without releasing harmful by-products. This solution is forced through spinnerets to create fibers, which are then washed, dried, and spun into yarn. More than ninety-nine percent of the solvent is recovered and reused, significantly reducing chemical waste and emissions.

This closed-loop system is the key reason lyocell is regarded as a sustainable fabric.

Physical and Chemical Properties

Lyocell fabric is known for its exceptional balance of comfort and performance. It has a naturally smooth surface that feels soft against the skin, often compared to silk or fine cotton. The fiber structure allows for excellent moisture absorption, making it highly breathable and ideal for warm climates.

Lyocell is also remarkably strong, even when wet, which improves durability and longevity. It resists wrinkling better than traditional rayon and maintains color vibrancy after repeated washing. The fabric has natural temperature-regulating and antibacterial properties, contributing to its suitability for sensitive skin.

Uses and Applications of Lyocell Fabric

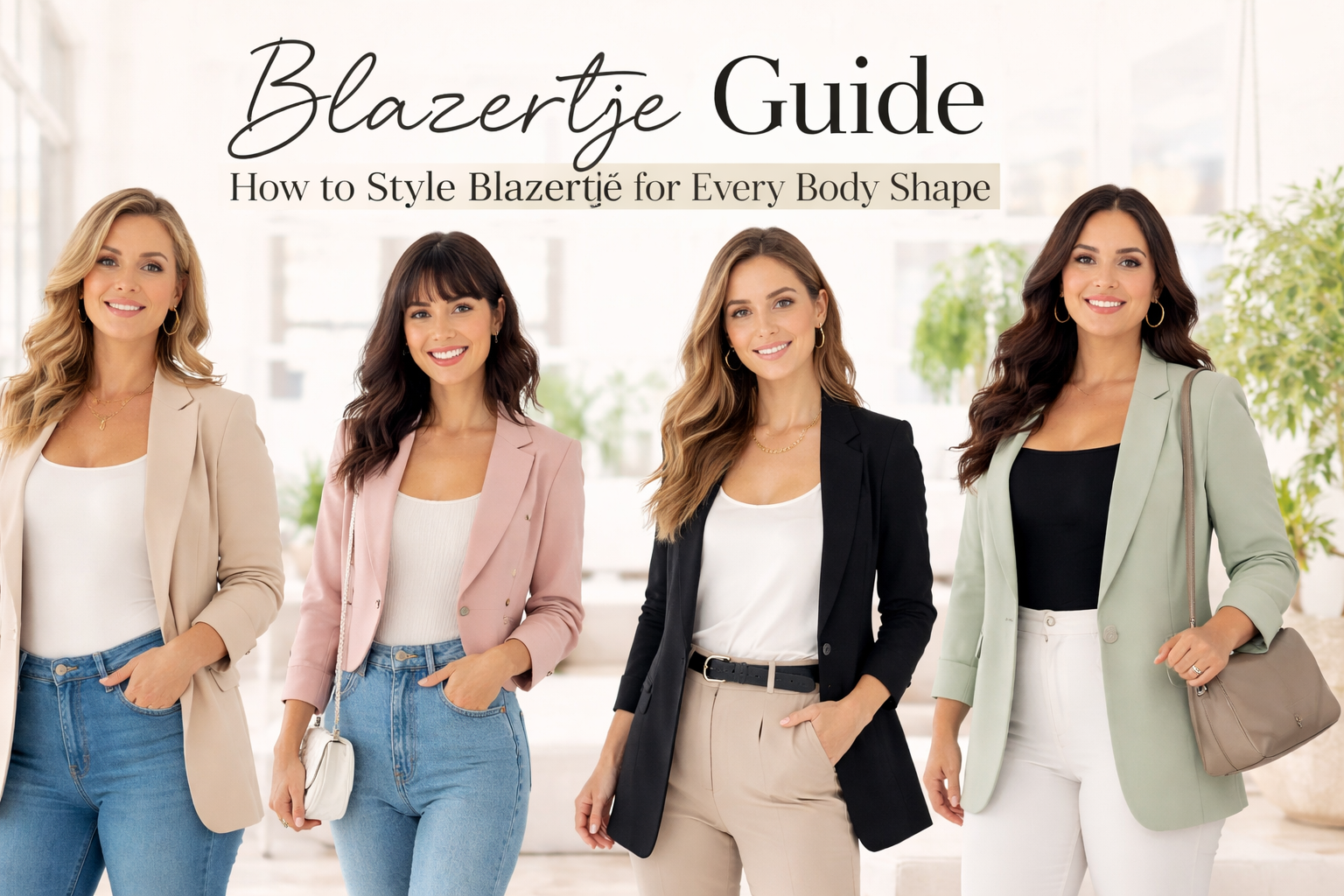

Lyocell fabric is widely used across multiple industries due to its adaptability. In fashion, it is commonly found in shirts, dresses, trousers, denim blends, underwear, and activewear. Its softness and breathability make it especially popular in summer clothing and luxury apparel.

In home textiles, lyocell is used for bed sheets, pillowcases, towels, and upholstery fabrics. The medical and hygiene sectors also utilize lyocell for wound dressings, surgical garments, and baby products because of its hypoallergenic nature and moisture control.

Environmental Impact and Sustainability of Lyocell

Sustainability is at the core of lyocell fabric’s appeal. The use of renewable wood sources, reduced water consumption, and recyclable solvents significantly lower its environmental footprint compared to cotton and conventional viscose. Lyocell fibers are biodegradable and compostable under appropriate conditions, making them compatible with circular fashion models.

Responsible forestry practices further enhance lyocell’s eco-credentials, as trees used for pulp are replanted and harvested under strict environmental guidelines.

Advantages of Lyocell Fabric

Lyocell offers numerous advantages that contribute to its growing popularity. It provides superior comfort, excellent moisture management, long-lasting durability, and a luxurious appearance. From an environmental perspective, it represents a more sustainable alternative to many conventional fabrics. Its versatility allows it to blend well with cotton, wool, silk, and synthetic fibers, expanding its application range.

Limitations and Challenges of Lyocell

Despite its many benefits, lyocell fabric does have some limitations. It is generally more expensive than cotton or standard rayon due to its advanced production process. Improper care, such as excessive heat or harsh detergents, can affect its longevity. Additionally, limited consumer awareness in some regions has slowed its widespread adoption.

Lyocell Compared to Other Fabrics

When compared to cotton, lyocell offers better moisture control and a lower environmental impact. Compared to polyester, it is more breathable and biodegradable. Unlike traditional viscose, lyocell is produced using safer chemicals and generates significantly less pollution, making it a more responsible choice for sustainable fashion.

Future Research and Innovation

Future research in lyocell fabric focuses on improving efficiency, reducing production costs, and expanding applications. Scientists are exploring alternative bio-based solvents, enhanced fiber recycling methods, and improved blending techniques to create high-performance textiles. Innovations in circular fashion aim to enable complete fiber-to-fiber recycling, allowing lyocell garments to be reused without quality loss.

Advancements in smart textiles may also integrate lyocell with functional technologies such as temperature regulation, antimicrobial treatments, and wearable sensors, further broadening its role in the textile industry.

Conclusion

Lyocell fabric represents the future of sustainable textiles by combining environmental responsibility with premium performance. Its origins in renewable materials, clean manufacturing process, and wide range of applications make it an ideal solution for modern clothing and home textiles. As research continues and awareness grows, lyocell is expected to play a central role in shaping a more sustainable and ethical textile industry.